Lockout Tagout Signs

Every workplace environment requires regular cleaning and maintenance. Besides workplace cleaning, industrial equipment like heavy machinery needs regular maintenance or repairs. While all this is done to protect employees as well as employers safe in the work environment, there need to be certain safety mechanisms to avoid accidents while cleaning or handling equipment.

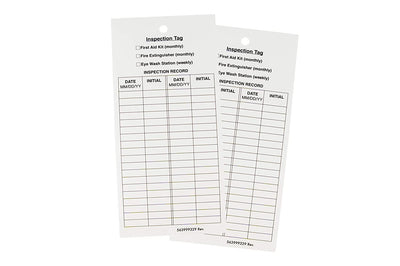

Lock Out Tag Out Tags

Lock Out Tag Out (LOTO) is one of the essential safety practices that every organization should have to provide protection to employees. There are LOTO tags designed to avoid accidents and help improve safety in an industrial environment. Using them during equipment maintenance or repairs can help dramatically reduce the risks and accidents associated.

Merely turning off the equipment or machinery is not always adequate during maintenance or repair. Someone could turn the machine back on, potentially causing serious injury or even death of the person.

Even if the industrial machinery or equipment is switched off, it has the potential of storing mechanical, electrical, or hydraulic energy, which will injure workers. The Lock Out Tag Out procedure or tags prevent employees from touching the machinery and avoid accidents.

The Lock Out Tag Out system blocks all incoming and stored energies in the equipment, making running impossible. Similarly, LOTO tags are standard labels or tags that explain why the equipment has been locked or tagged out and the information of people who locked or tagged out the system.

The Main Purpose of Lock Out & Tag Out

While the locks are used to physically secure energy isolation points without letting the equipment energize during maintenance or repair, tags are warning devices always used with locks to gain attention to the fact that the machinery is locked out. The tags don’t provide physical restraint on the device, unlike locks.

The Lock Out Tag Out goes hand-in-hand and works best when used together. You can’t just lock out a piece of equipment while performing repair or maintenance and leave it without placing a tag on it.

Employees may sometimes forget or just ignore warnings will succumb to injuries during an unexpected outburst of hazardous energy. This explains why the Lockout tags are essential for the employees’ safety in workplaces.

5 Reasons for Using Lock Out Tag Out

Keep Workers Safe from Injuries & Accidents

The main reason why Lockout tags are essential is that they help keep employees safe in the workplace. Heavy machinery and other equipment, if left unnoticed while maintenance or repairs, can pose dangers to people around them. The Lockout tags will help minimize the risk of injuries and prevent accidents keeping everyone safe in the environment.

Protect Equipment or Machinery from Workplace Damage

It is critical to make sure that your employees are working in a safe and accident-free environment. Following Lock Out Tag Out procedures and placing tags when necessary will reduce the incidences and increase the safety of workers as well as equipment in the workplace.

Reduce Downtime While Maximizing Production

An accident or injury in the workplace usually halts production to help the workplace victims. Also, the production is most likely to be stopped during the investigation of the cause. This will result in loss of productivity for hours and even for days depending on the case. Besides, it will impact the overall output and the bottom line of a business. Avoiding workplace accidents will potentially save the company a large sum of money in repair costs.

Build Trust & Confidence in Employees

Employees are the most significant asset to an organization, and it’s the employer’s responsibility to keep them safe in workplaces. Implementing a proper Lock Out Tag Out safety mechanism and using Lock Out tags portray the unprecedented commitment of the organization towards its employees.

Working in a safe and risk-free environment also builds trust and confidence among employees. They feel empowered and work with confidence when they are secured.

Meet OSHA Compliance

Above all these reasons, it is necessary that every organization should meet the OSHA mandates. The legal guidelines, compliances, and formalities should be met to avoid regulatory fines and serious consequences. Moreover, workplace accidents can ruin the name and prestige of an organization.

These reasons make it clear that the Lock Out Tag Out is essential for all facilities. It is not just a matter of compliance but also an important investment in safety. Get the highest quality Lockout tags from Bison Life at competitive costs and guarantee your employees’ safety in the workplace.

FAQs:

The three essential elements that OSHA requires on a lockout/tag out include training, inspections, and written procedures. The training must be given to both authorized and affected employees. The Lockout/Tagout procedure keeps the employees safe from equipment or heavy machinery that could cause injuries or accidents if not handled correctly.

The LOTO requires employers to ensure the equipment or machinery is kept safe with Lockout tags while they are shut down or inoperable due to maintenance or repair works. The LOTO tags help keeps workers safe from potential injuries or accidents, warning them not to use them during maintenance or repair.

The Lockout/Tagout should be used when someone has to service or repair the machine. They should always be turned off and locked out to keep the maintenance personnel as well as employees safe. Simply turning off the machine or equipment doesn’t serve the purpose, and hence the lockout/Tagout mechanism should be in place for safety.

The lockout/Tagout is safety and life-saving device that protects the employees from injuries or accidents when used correctly as per the given LOTO procedures. Hazardous energies are released even when the machinery is shut off, so the Lockout/Tagout is vital to keep the person safe from dangers during maintenance or repairs. LOTO also reduces accidents and increases the safety of equipment and workplaces.

The Lockout locks are usually standardized in color, size, or shape as per a company's Lockout/Tagout policy. Using red locks or devices is the best practice in most industrial facilities, but some organizations find it helpful to use different colored locks for various departments.

As a general rule, only the worker or service personnel who applied it can remove the Lockout/Tagout device from an energy isolating device. Removing locks without adequate knowledge can be dangerous and must be avoided. According to OSHA's regulation, if the authorized employee who applied the Lockout/Tagout is not available, then the device can be removed under the employer’s direction, provided that specific procedures and training for such removal have been given.